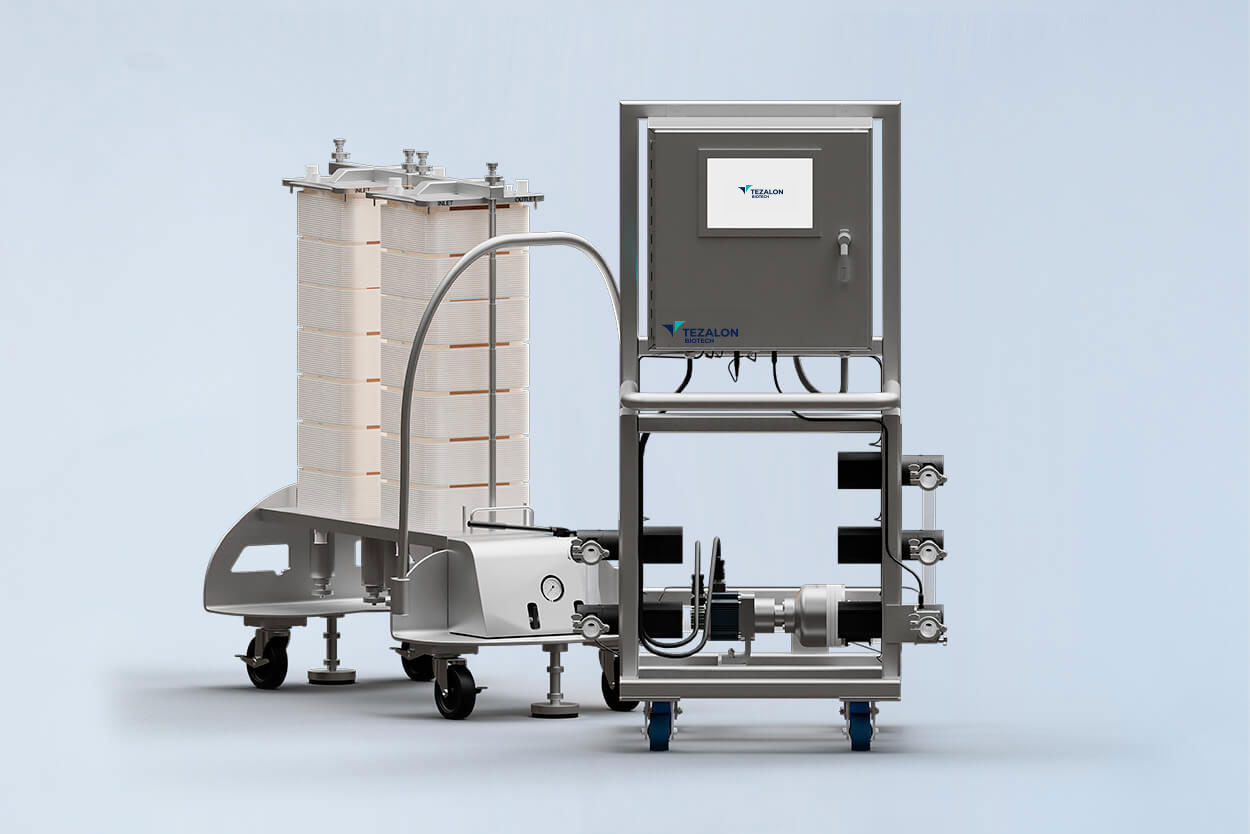

Multipurpose Single-Use Filtration Systems

One product configurable for multiple bioprocessing steps: depth filtration, virus filtration, and sterile filtration.

One product, multiple applications.

Flexible 3-in-1 design can be adapted to virtually any external filtration system for depth filtration, virus filtration, and sterile filtration.

Expectations for biomanufacturing require downstream systems to be responsive and flexible to meet ever-changing demands and requirements. And the new single-use multipurpose filtration system is designed with this in mind, providing next level flexibility to meet the needs of customers now and as their bioprocesses evolve.

The Tezalon Advantage:

Flexible brand-agnostic design enables use of best-in-class components for every part of the system

Multiple inlets and outlets provide even more flexibility to meet your exact needs

Manual operation to fully automated control with your preferred automation and control platform (DeltaV®, Rockwell Automation®, or other)

Space-saving compact benchtop and floorstanding model with castors for easy moving

Dynamic flow control, volume totalizer, and more features to optimize your bioprocess!

How it works

The physical aspects of the multipurpose filtration skid are the same from one application to the next and the skid is not set up initially to be technically configured to a specific filter. To configure the skid for a specific application, the appropriate filter is first physically connected to the skid, whether a depth filter, virus filter, or sterile filter. Next, parameters such as optimized flow rate and pressure requirements of the filter are configured for the appropriate application. The system can be used for one step of the filtration process and then configured for another step, as needed. Shown here is the floorstanding model configured for depth, virus, and sterile filtration.

Depth Filtration Configuration

Virus Filtration Configuration

Sterile Filtration Configuration

Quality consumables customized for your unique process

The components integrated with Tezalon single-use systems, such as flow path assemblies and 2D/3D bags, are manufactured to the highest standards to ensure exceptional quality and operational excellence. These consumables are designed with precision and tailored to meet the unique requirements of your processes, offering reliability and consistency for your operations.

- Customized Flow Path Assemblies: Integrated sensors and sterile-to-sterile connections, tailored for specific batch sizes; compatible with various filters and instrumentation.

- 2D Bags: Scalable based on batch size with customizable inlet and outlet ports.

- 3D Bags: Scalable to any size up to 2500L with customizable inlet, outlet, sampling, and instrumentation ports.

This level of customization ensures our solutions meet the rigorous demands of your workflow while supporting process efficiency and flexibility.

Download product information and other featured content:

Single-use Multipurpose Filtration Systems

Configurable for Depth, Virus, Sterile Filtration

1.1 MB

Service and support to fit your exact needs

All Tezalon single-use technologies are built to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

And if you need more, we will partner with you to develop Performance Qualification (PQ) testing; supplemental documents such as Qualification Project Plan (QPP), Criticality Assessment and Risk Assessment can also be provided.

All Tezalon single-use systems are delivered with a recommended preventative maintenance plan and spare parts list. We also provide maintenance service to ensure pumps, transmitters and all other components function within specification.

You have a vision for your process.

We can help you get there.